How to Install a Mercedes Convertible Soft Car Top

TOOL/MATERIALS REQUIRED

Phillips & Slotted Screwdriver --Scissors --Marking pencil or Chalk --Metric

socket set.

Blunt stuffing tool(rounded putty knife)--Awl

Spray Adhesive 1 can. or Brush Adhesive, quart

Pulling wire

Weatherseal Adh. black #9412--Silicone Adh. Black #9413

Protective blankets --Masking tape

Pliers or Vice Grips--Hooked tool

ADDITIONAL PARTS THAT MAYBE REQUIRED

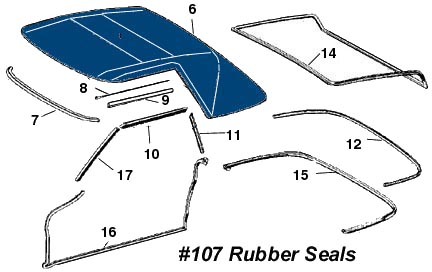

Top Straps, pr. #107-3056 (not illustrated)

#7=Top to windshield weatherseal #107-2196,

#10=Door glass to top frame weatherseal, horizontal #107-2199, 2 req.

#11=Door glass to top frame weatherseal, verticle #107-2200, 2 req.

#17=A post weatherseal #107-2291/2202, 2 req.

#12=Top to rear deck lid weatherseal #107-2198,

#8=Side cables (pr) 107-2195,

#9=horizontal side seal is included with all STF or German canvas tops

Call for pricing.

Preparation